Blast-furnace production

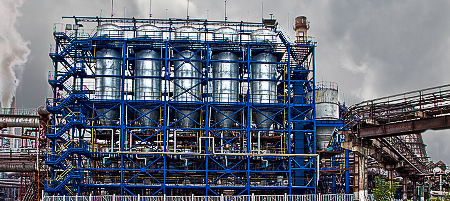

The structure of the blast furnace technological process includes the following divisions:

- Ч stockyard and lower feed

- Ч coke feed

- Ч blast furnaces

- Ч casting machines

- Ч stockyard of cold iron

- Ч site for preparation of refractory materials and thermal compounds

- Ч granulating pool

- Ч slag-heap

The shop has three blast furnaces:

- Ч BF є1, useful volume is 1066 m3 (HD 7.2 m);

- Ч BF є2, useful volume is 462 m3 (HD 4.9 m);

- Ч BF є3, useful volume 740 m3 (HD 6.0 m)

The complex of each furnace includes: a slope bridge with an inclined skip hoist, a casting yard, a dust collecting system and a gas pipeline of dirty and clean gas.

Qualified staff and modern equipment allow JSC УKGIWФ to produce foundry (State Standard 4832-95) and cast (State Standard 805-95) pig iron of all brands under existing international and Russian standards, including nodular, which is used in the smelting of critical parts in automotive and other high-tech industries, as well as ferromanganese (State Standard 4755-91).