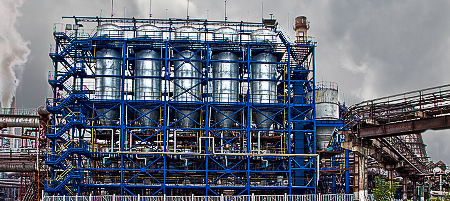

Industrial casting

For many years the foundry of KGIW makes products of high quality for the metallurgical enterprises.

The existing corporate culture allows foundry shop of JSC KGIW to make products that fully meet international standards.

Among our partners are such plants as Gorky Metallurgical Plant, Zlatoust Metallurgical Plant, MoscowТs Metallurgical Plant "Serp i Molot" and many others.

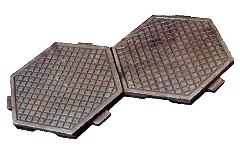

Cooling plates of high-strength iron

Since 2004, the foundry has successfully mastered the technology of casting of cooling plates for blast furnaces out of high-strength iron (the method of cast iron modifying was developed and patented by the Company).

Refrigerators of this type of cast iron surpass the performance of the products made of grey iron:

- strength characteristics are 2,5-3 times higher

- thermal conductivity factor is 2 times higher

In 10 monthsТ period, from 2008 to 2009, 426 cooling plates with total weight of 960 tons were molded by JSC KGIW for the overhaul of BF є 1. Particular attention was given to the production of coils. Coils were made of steel pipe with 6 mm wall thickness, moreover, only one welding seam was allowed provided that the expanded length of the coil was more than 4 m. Also a special coating was applied in order to prevent the pipe material from carbonization while metal casting.

Precision of manufacturing and purity of surface finish allowed, while installation of cooling plates on the blast furnace, to do without additional fitting, grinding or other operations affecting the stability of installed cooling elements.

Steel castings

Since the commissioning of furnace IST2 the foundry of JSC KGIW in the shortest time successfully mastered the production of a wide range of steel castings for the steel industry:

- moulds,

- crucibles,

- pivots,

- boxes,

- gutters,

- pallets,

- embrasures,

- skimmers, and much more.

Produced by the foundry of JSC KGIW steel boxes for blast furnace filling machines showed excellent resistance and on the basic parameters and characteristics are not inferior to the best examples of the competitors.

Download presentation of industrial casting in Microsoft PowerPoint format